7 steps to choosing the right shelving

The purpose of shelving is not only to organize stock and optimize workshop or warehouse space, but also to streamline and organize the various tasks involved, thereby boosting productivity.

Whether you're looking to set up a storage area, equip a warehouse, organize an evolving archive, optimize available space... There are many different storage needs, which is why it's important to make the right choice of shelving according to your storage project.

To think about all the criteria that influence your choice of shelving, follow the guide.

Step 1 - Loads to be stored per level

The weight of the load to be stored is important in determining the load per level, and therefore the type of racking. It is dangerous to store heavy products on light shelving.

Light loads: less than 250 kg

Light duty racking is ideal for products that can be handled manually or with the aid of a stepladder. These racks are designed to store files, documents, archives, suspension files, plastic containers, small materials and small parcels. We recommend them for offices, libraries, archive areas, workshops and storerooms, backrooms and retail outlets.

Medium-heavy loads: between 250 and 900 kg

Medium-weight shelving is ideal for industrial installations storing bulky or medium-heavy products such as cartons, tires, clothing, spare parts, large parcels or paintings. They can be installed in workshops, archiving areas, warehouses, museums, etc. They are made up of ladders and stringers, also known as beams.

Heavy loads: over 900 kg

Heavy-duty shelving can store up to several tons of palletized products or specific loads such as boats, cars or long loads. They are designed for stores, warehouses and factories. For heavy-duty shelving with longitudinal beams, the load chart will help determine the type of longitudinal beams to use

Step 2 - Types of goods

The size and shape of the objects to be stored are also essential elements to take into account. If you need to store and sort specific products, certain shelving systems can be adapted to their dimensions: small and unpackaged sizes, large cartons or products, long products (tubes, pipes, bars, etc.), specific materials (drums, tires, etc.).

Step 3 - Rotation frequency and product type

The nature of the products and the rotation frequency must be taken into account when choosing a storage solution. Depending on your inventory management method and supply chain, the choice of racking may be different. You may opt for fixed, dynamic or accumulation storage, using storage methods such as the ABC method, or the L.I.F.O and F.I.F.O methods.

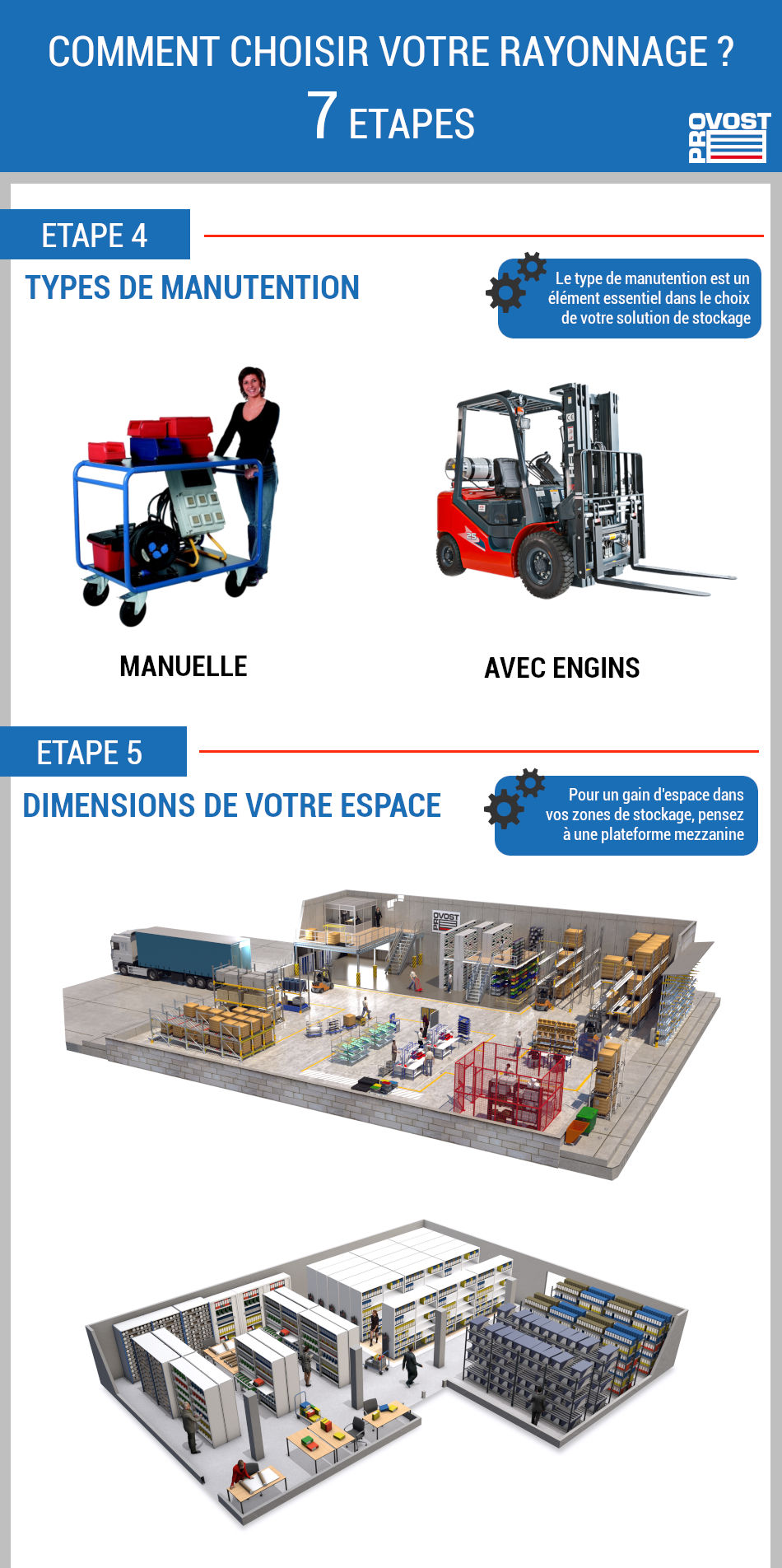

Step 4 - Types of handling

The type of handling is a key factor in your choice of storage solution. If you decide to handle your products manually (by hand, hand-push carts, assembly on station using stackers, etc.), the optimal shelving solution may be different from that used by pallet trucks, stackers, forklift trucks, small-train carts, etc

Step 5 - Dimensions of your storage space

To better adapt to your space, our shelving is available in different heights, lengths and depths. If you need to save space, or if you want to compact your storage shelves, you can opt for a space-saving mobile shelving solution. If you've got room to spare, consider a mezzanine storage platform to save space in your dedicated areas.

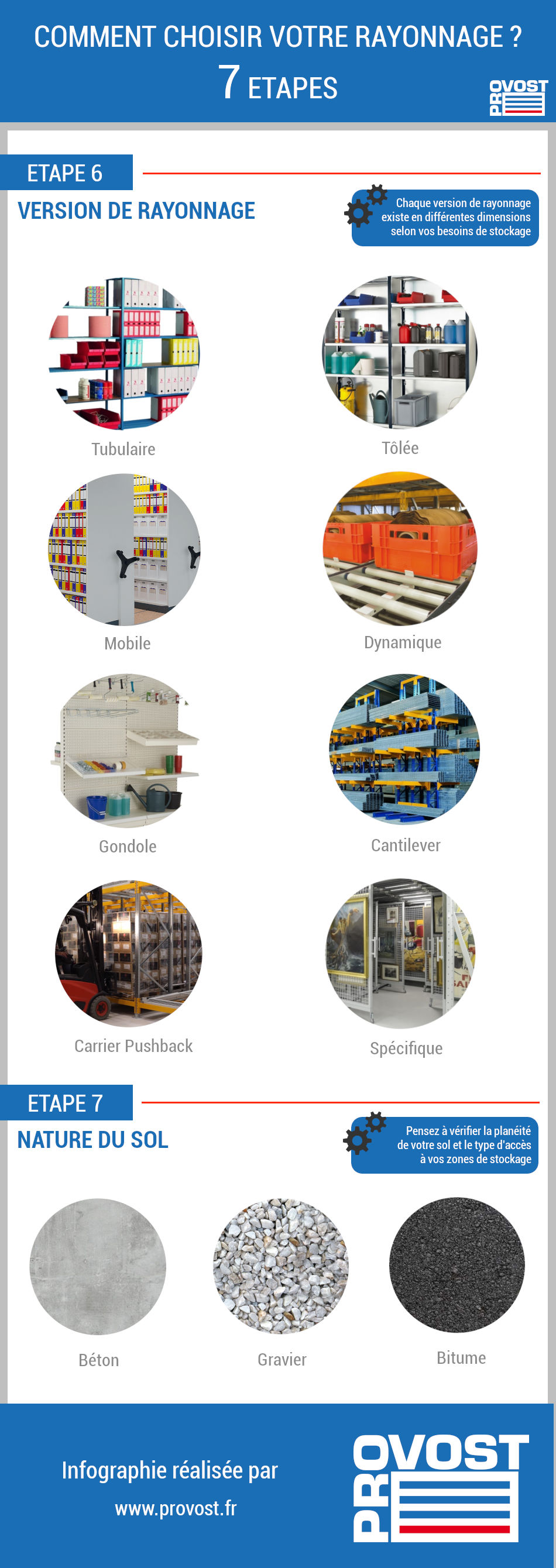

Step 6 - Racking versions

Each shelving version meets a different need, so it's vital not to forget the previous steps to make the right shelving choice next.

Tubular shelving, sheet metal shelving

Our metal shelving comes in several versions. For light shelving, you can choose either tubular or sheet metal shelving. Tubular shelving, consisting of uprights and shelves only, is often a more economical solution, and is very easy to assemble. Sheet metal shelving is available in 3 versions: open version (more economical), version with sheet metal sides, version with sheet metal sides and bottom.

Mobile shelving

To compact your archives, we recommend you choose mobile archive shelving, which can be moved on rails to save time and space.

Dynamic shelving

To facilitate order preparation and optimize logistical picking, consider dynamic shelving, which allows you to store totes and cartons by gravity and move them forward using a roller system.

Gondolas and shelving

We also recommend gondolas for displaying your products in stores and stores. These shelving units and gondola racks are designed for displaying goods in your sales areas, but also for product storage, wholesale, DIY..

Cantilever racks

Cantilever racks are ideal for storing long loads. Cantilever racks are designed to store long loads such as beams, metal sections, tubes, pipes, wooden panels, etc

Pallet rack, pallet racking

Pallet storage comes in a variety of versions. You can opt for dynamic storage, or accumulative storage with the carrier pushback, suitable for medium-rotation goods, or high-density storage with the pallet shuttle, a motorized loading and unloading solution.

Step 7 - Nature of the floor

It's important to take into account the nature of the ground (concrete, gravel, earth, asphalt, etc.) to determine whether you simply need to lay down your shelving or fix it in place. Don't forget to check the flatness of your floor and the type of access to your storage areas.