Choosing your pallet racking solution

There are many pallet racking solutions to optimize warehouse storage. Depending on your logistical needs, the amount of storage space available and the type of merchandise, the right solution will differ.

This guide will help you discover :

- important criteria to consider,

- the different types of pallet racking available,

- and how to organize your storage racks.

Choosing your pallet rack: important criteria

It's essential toinspect your storage location, taking into account :

- Available floor space;

- The height of your storage building;

- The space required for handling and lifting equipment (stacker, pallet truck, forklift);

- The storage environment (logistics warehouse, outdoor, controlled or negative cold).

When it comes to your pallets, you need to take into account :

- Pallet size and weight;

- The total number of pallets to be stored on this surface;

- The number of pallets per reference.

It's also very important to consider the type of goods you want to store:

- Known incoming and outgoing flows of your goods;

- The perishable or sensitive nature of the goods (foodstuffs, chemicals, fresh produce, etc.);

- The number of different product references to be stored.

Other constraints also need to be taken into account:

- The type of forklift used, which determines the system's maximum removal height and aisle width;

- The skill and safety of forklift operators;

- Your budget.

Pallet storage solutions

Based on all these criteria, you can determine which racking solution best suits your needs: fixed single- or double-entry racking, accumulation racking, dynamic racking (on carts or rollers) or shuttle racking.

Single or double entry fixed pallet rack

It's the ideal solution for storing heavy or bulky products in complete safety. Its variants can be adapted to your needs and logistics flows. This system is recommended for a large number of references, but with a low volume per reference.

How the solution works :

This solution is adapted to the ABC storage method, which consists in storing goods according to their turnover rate (the higher the turnover, the closer the goods are placed to the operators, and therefore easier to handle).

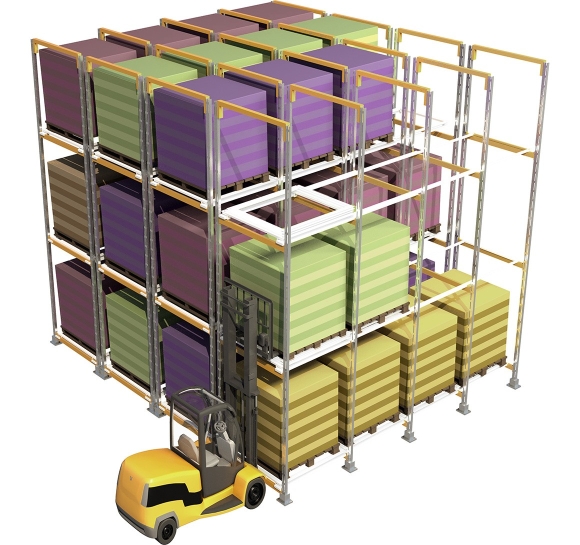

Accumulation storage rack

This storage solution for palletized loads is recommended for large volumes with a limited number of part numbers. With this pallet storage solution, the truck enters the aisles to load or unload the pallets, whatever the level to be reached.

How the solution works :

- Drive In : Pallets are loaded and unloaded from the same side on the LIFO (Last In - First Out) principle;

- Drive Through: Pallets are loaded from one side and unloaded from the opposite side on the FIFO (First In - First Out) principle.

Dynamic pallet racking on cart: Carrier Pushback

The Carrier Pushback pallet racking system is a dynamic pallet racking system on mobile carts. It canstore up to 9 pallets deep. This solution complies with the LIFO (Last In - First Out) method, and enables one reference to be stored per location.

How the solution works :

- Pallets are deposited at the entrance to the aisle on a mobile frame sliding on a metal rail;

- The pallets move by pushing when loaded, and by gravity when unloaded.

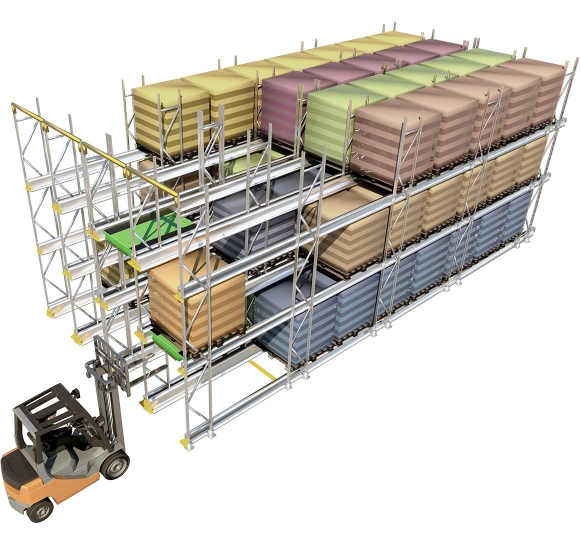

Dynamic pallet rack on rollers

This is a dynamic storage system with large rollers, where pallets move by gravity. It enables the storage of a very large number of pallets of the same reference on each dynamic line.

How the solution works :

- FIFO (First In - First Out): pallets are loaded and unloaded on opposite sides. The pallet is deposited on one side, and descends by gravity to the other, where it is unloaded. This enables a very large number of pallets to be stored in depth;

- LIFO (Last In - First Out) : lines are loaded and unloaded from the same side. During loading, pallets are pushed back. When unloading, pallets move by gravity. However, the number of pallets stored in depth is limited by the weight of your pallets.

High-density pallet shuttle storage

This solution is designed to increase pallet storage density and optimize logistics flows. It is ideal for fast-moving, high-volume products. With the high-density pallet rack, it's possible to store one reference per level, and a very large number of pallets deep down. This solution is suitable for LIFO (Last In - First Out) or FIFO (First In - First Out) methods. It is also possible (as an option) to store pallets of different depths.

How the solution works :

- The shuttle is deposited at the entrance to the aisle and moves along a rail inside the system;

- The shuttle moves the pallet to the first available location and back, and vice versa;

- The pallet shuttle is fully electric, equipped with a lithium battery and operated by remote control;

- This solution is also suitable for low-temperature warehouses;

- The pallet shuttle eliminates the need to purchase special forklift trucks to enter pallet racks.

All our storage solutions at a glance

Here's a summary of all our storage solutions and their features.

| Pallet storage | Products | Type of storage | Storage density | No. of different references | Method | Machines entering the installation | Nb of pallets in depth |

| On pallet rack | PROPAL 3 | Fixed | Low | Many references Few pallets per reference |

ABC | - | 1 2 for double-sided |

| By accumulation | PROPAL 3 | Fixed | High | Low 1 part number / color over the entire height | LIFO OR FIFO | Yes, with specific machine | Limited by danger to operator and installation |

| On mobile trucks | CARRIER PUSHBACK | Gravity dynamics | Medium | 1 reference / aisle | LIFO | No | Up to 9 |

| With motorized shuttle | SHUTTLE | Dynamic | High | 1 reference / lane | LIFO OR FIFO | No | Very high |

| On rolls | PRODYN+ | Gravity dynamics | High | 1 reference / lane | LIFO OR FIFO | No | Depending on weight and number of pallets |

How to organize your pallet rack?

Here are a few tips on how to organize your pallet racking to save space and improve safety.

Leave enough space:

- Makesure your aisles are wide enough for your handling equipment: forklifts, hand trucks, pallet trucks, etc. The wider the aisles, the lower the risk of bumps and falls.

- Check that the dimensions of your pallets are appropriate for the space in which they will be stored.

- Respect the level heights indicatedon the load plates supplied by the manufacturer.

- Leave enough empty space above your pallets so that you can easily remove them with your forklift truck, without any risk of impact that could damage the structure. Avoid stacking too many products on your pallets.

Avoid overloading your pallets:

- Do not exceed the loads specified by the manufacturer, as this will weaken the structure.

- Check that your racks are fitted with load plates: these must be positioned by the manufacturer on all your racks, and enable forklift truck operators to respect the load possible on each compartment. Make sure they are present and legible.

- Distribute loads evenly on your pallet racking, ensuring top/bottom, front/back and left/right balance.

- Center your pallets on your racks: your pallets should protrude slightly from your racks (the distance specified in standard EN-15-620, depending on the characteristics of your racks). However, this distance must be equivalent at the front and rear of the pallet.

Keep your shelving in good condition:

- Payclose attention to the general condition of your pallet rack: squeaking, shaking or deformed beams should alert you.

- Use pallets in good condition: if any slats give way, there's a risk that the contents of your pallets will fall out.

- Have your pallets inspected annually by a competent professional (in accordance with standard NF EN 15635). This inspection includes

- Rack safety check.

- Visual inspection of uprights and rails,

- Presence of safety and signalling devices.

- Condition of pallets.

- Condition of floors.

Provost experts are at your disposal for a free audit.

Interested in our pallet racking solutions?

At Provost, we offer a range of metal pallet racking solutions to suit any configuration. Made from high-strength steel, our pallet racking system can store heavy loads of up to 6 tons per storage level. Available in a wide range of formats for all your projects: 28 ladder heights - 10 depths. Ladders are adjustable in 50 mm increments, and can support very high load capacities. For outdoor storage, you can opt for galvanized racking.