Racking and picking guide

Whether you need to store spare parts, beaker bins, stacking bins, parcels or even tires... Find out which storage system is best suited to your needs!

Professional shelving allows you to store on tubular shelves, wire shelves or inclined levels to facilitate product picking.

If your business requires a FIFO First-in, First-out system, we recommend a dynamic storage system.

If you want to optimize the height of your warehouse, our sales team can also recommend the use of a storage platform. Depending on the width of your product range and the nature of your business, we can advise you on a range of options.

High turnover storage on aisle racks - Picking

Principle: the storage of small parts (cartons, boxes, textiles, automotive parts) with a small footprint and high turnover requires an in-depth study of flows.

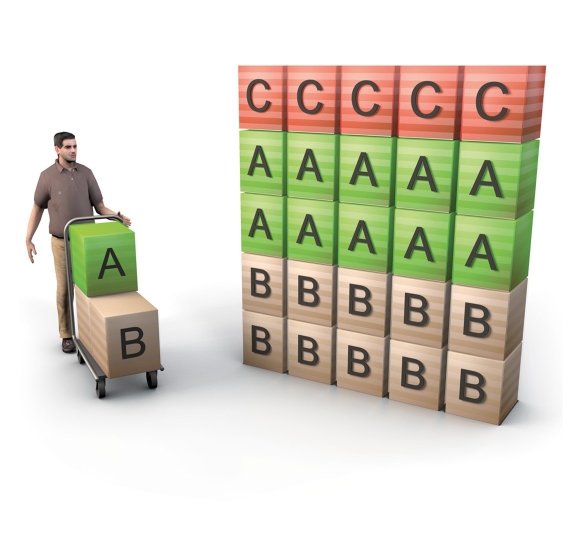

According to the ABC method, fast-moving goods will be stored close to access points and close to the main aisles, at hand-height. Slow-moving goods will be stored at the end of aisles, at the bottom and top of shelves.

Similarly, heavy goods are stored at the bottom and light goods at the top. The shelving against the walls has single access, while the shelving in the aisles has double access.

For ergonomic reasons, height is limited to 2,000 mm, and means of access such as stepladders are avoided.

Shelving can be fitted with the following accessories:

- Sheet metal or wire dividers to delimit picking compartments

- Aisle signs, label holders

Handling is carried out by :

- Picking carts corresponding to a certain number of orders to be prepared

- Plastic bins, cardboard bins, wire baskets

Dynamic storage on FIFO rails

After an in-depth study of a company's manufacturing and assembly flows and processes, we can determine a dynamic gravity storage system on rollers.

The rack frontage and number of lanes correspond to the number of part numbers required to assemble the finished product. One reference = one conveyor rail.

Rack depth corresponds to the amount of product consumed between two replenishments.

Work organization is Taylorized and shift-based.

One operator supplies the rack, while another picks the required references.

Racks can be equipped with :

- Shelf supports

- Orientation rails

- Empty pack deposit table

Handling is mainly carried out using plastic bins, which can be folded when empty.

The racking can be equipped with a picking-by-light system, and the workstation designed according to the operator's task.

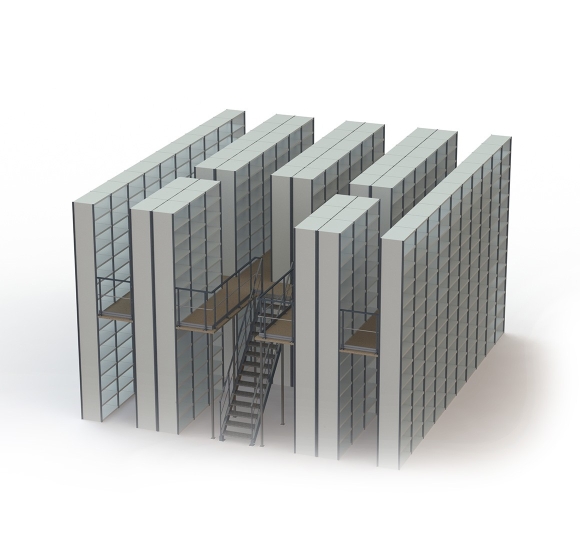

Platform storage with aisles

In order to optimize the height of a building, one or two upper picking levels can be built directly onto the shelving, a solution which is not very flexible and is particularly well suited to companies with homogeneous loads: mail order, textiles, publishing, etc. The function of the upper levels is identical to that of the ground floor, as they are an extension of the lower level shelving.

If rolling loads (picking carts, pallet trucks) circulate on the upper levels, this must be taken into account when calculating the solution. This type of installation is subject to DRIRE authorization for personnel evacuation, clearance and fire safety regulations.

The system can be fitted with the following accessories:

- Main and secondary staircases

- Lock barriers, railings

It can be fitted with external elements such as conveyors and various handling solutions.

Storage with single-level platform

The single-level platform meets the same needs as the driveway platform, with the difference that the use of the upper level is independent of that of the ground floor.

On the ground floor, a conventional aisle system is used. The first floor consists of a single level that can be used for offices, pallet storage or new shelving.

Shelving on the upper level may differ from that on the first floor in terms of direction, size and aisle width.

If rolling loads (picking carts, pallet trucks) circulate on the upper floor, this must be taken into account when calculating the solution. This type of installation is subject to DRIRE authorization.

The system can be fitted with the following accessories:

- Main and secondary staircases

- Lock barriers, railings

- Modular partition offices

- Storage areas in wire mesh walls

It can accommodate external elements such as conveyors and handling equipment.

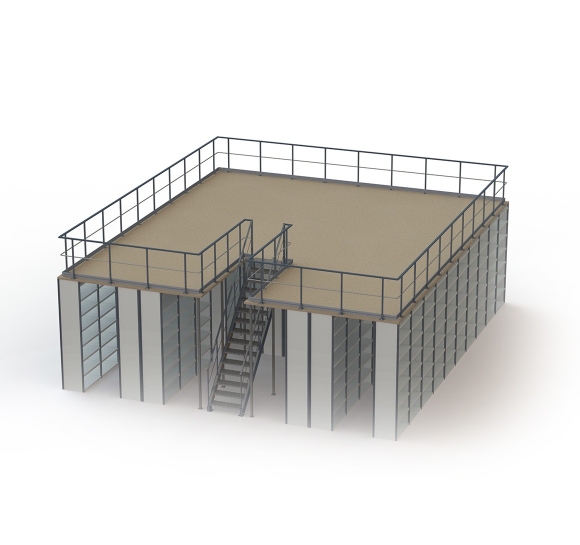

Storage on pole platform

The mezzanine platform with posts meets the same needs as the platform with aisles, with the difference that the use of the upper floor is independent of that of the ground floor.

Both the ground floor and the first floor have two clear zones, enabling the creation of independent installations with shelving, storage areas, office space, etc. The long span of the beams frees up floor space with a minimum of columns. If rolling loads (picking carts, pallet trucks) circulate on the floor, this must be taken into account when calculating the solution.

This type of installation is subject to DRIRE authorization.

The system can be fitted with the following accessories:

- Main and secondary staircases

- Lock barriers, railings

- Modular partition offices

- Storage areas in wire mesh partitions

- Struts and chain braces

It can accommodate external elements such as conveyors and handling solutions.