Storage: how to optimize it?

Provost, France's leading manufacturer of shelving and storage solutions, invites you to discover the main inventory management methods for efficiently organizing the storage of your items, raw materials and finished products in your logistics warehouses...

Methods and solutions for optimizing your storage and logistics flows

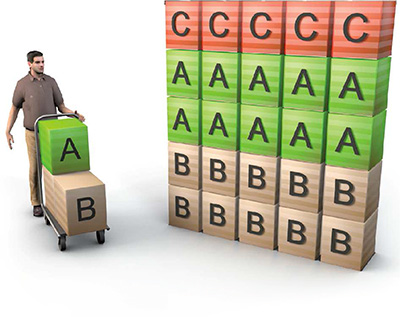

ABC method

The ABC (Activity Based Coasting)storage method is a technique for segmenting a company's various activities, in order to analyze costs and assess the profitability of each item. Based on this study, goods can be stored according to their turnover rate: the higher the rate, the closer the goods are to the operators and the easier they are to handle.

Principle of the ABC method

A: 80% of rotations and 20% of SKUs

B: 15% of rotations and 30% of SKUs

C : 5% of rotations and 50% of references

Storage with manual handling

In manual handling and picking storage, goods must be stored :

- A: at gripping height ;

- B: at the bottom of shelves;

- C: at height.

Warehouse storage

In the warehouse, goods must be stored :

- A: beginning of warehouse, close to goods-in and goods-out;

- B: middle of warehouse, close to goods in and out;

- C: back of warehouse and aisles.

Stock optimization

The aim of this method is to organize the available storage space in the best possible way, while leaving room for handling by the operator or the forks of the forklift truck. It has a direct impact on the choice of storage equipment.

The handling clearance required will vary according to the type of product to be stored

- Storage of archives: almost zero clearance to optimize storage;

- Storage of light loads with manual handling: a lateral clearance (L) and a high clearance (H) of a few centimetres are sufficient for gripping the goods;

- Storage of heavy loads, pallets with handling equipment: a lateral clearance of 75mm (L) and a high clearance of 100mm (H) are recommended.

Optimizing LIFO - FIFO flows

These two storage methods are designed to organize the flow of finished products or spare parts, but also to optimize inventory.

- LIFO (Last In - First Out): the last products to enter the warehouse are the first to leave, both physically and in accounting terms. As the last deliveries are (depending on the storage system) often more quickly accessible, it is quicker for the operator to pick directly from the last arrivals. If the products handled by the company have no use-by date problems, this inventory management model can be consistent.

- FIFO (First In - First Out): the first products to enter stock are the first to leave, both physically and in accounting terms. This method can be used to solve problems of deterioration over time. This applies, for example, to perishable goods or product obsolescence.

LIFO (Last In - First Out)

"Last In - First Out

Principle of single-access stacking and handling. This method is used with accumulation storage

FIFO (First in - First Out)

"First in - first out

Principle of dynamic storage with double-access handling

Methods and solutions for optimizing overhead storage

Mezzanine storage

Mezzanine storage platforms are extremely flexible in use and implementation, enabling you to optimize warehouse heights by doubling or tripling storage areas.

Combined with fixed storage elements or conveyors, industrial platforms can be used to increase stock density.

This modular system easily adapts to changes in activity: expansion, changes in stock levels...

It can also be adapted to changes in a company, for example by converting a storage area into offices.

Do you have a project?

Our 80-strong sales team in 12 branches across France, backed up by our 20-strong design office, can help you with all your needs.

I've got a project!