Heavy-duty racking guide, pallet storage

There are many solutions for installing pallet racking to optimize industrial storage in warehouses. The best solution will vary according to your logistical needs, the amount of storage space available and the type of goods you carry. The purpose of this guide is to give you some food for thought when choosing your pallet storage solution for your logistics warehouses.

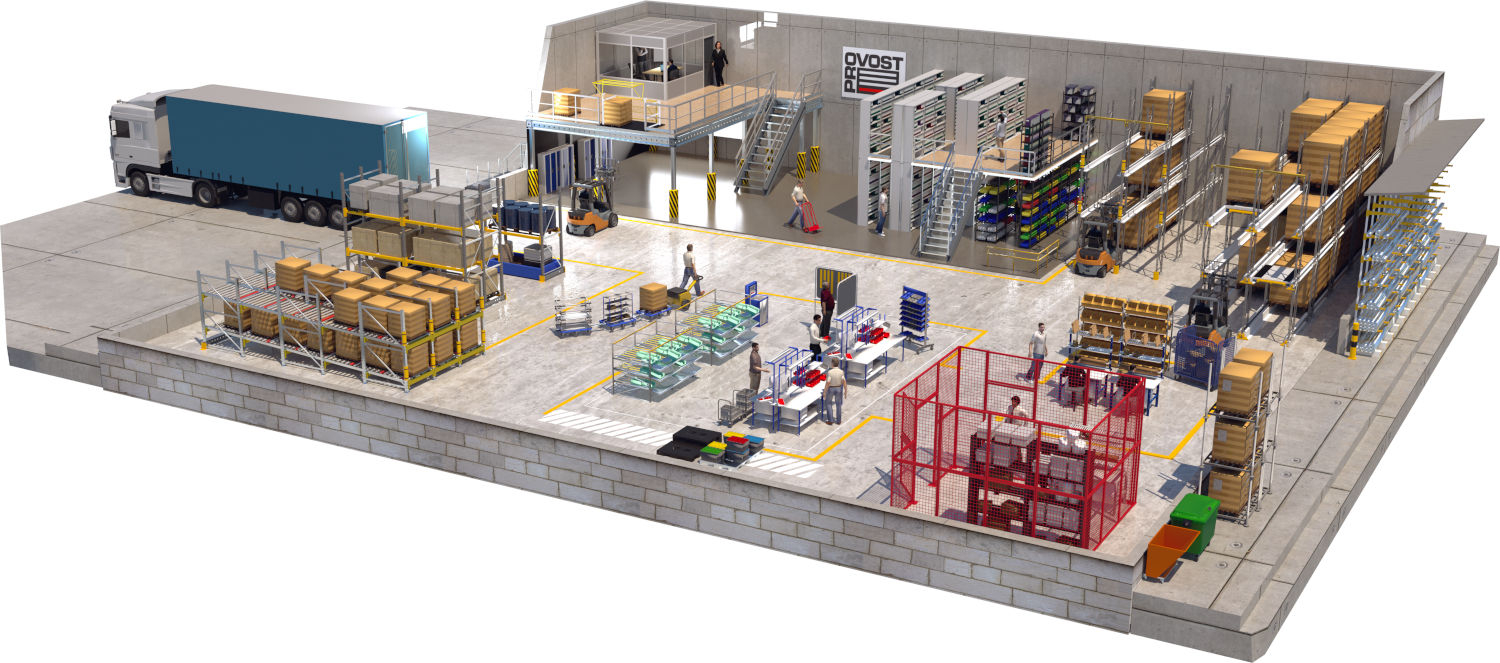

At Provost, we offer a range of metal pallet racking solutions to suit every configuration. Made from high-strength steels, our pallet racking system can store heavy loads of up to 6 tonnes on each storage level. Available in a wide range of formats for all your projects: 28 ladder heights - 10 depths. Ladders are adjustable in 50 mm increments, and can support very high load capacities. For outdoor storage, you can opt for galvanized racking.

Choosing your pallet racking solution: important criteria

Your storage space

It's vital to inspect your storage location, taking into account:

- Available floor space ;

- The height of your storage building;

- The space required for handling and lifting equipment (stacker, pallet truck, forklift);

- Storage environment (logistics warehouse, outdoor, controlled or negative cold).

Pallets

You need to take into account

- Pallet size and weight;

- Total number of pallets to be stored in this area;

- The number of pallets per reference.

Your goods

It's very important to consider the type of goods you want to store (cartons, totes, etc.):

- Known incoming and outgoing flows of your goods;

- The perishable or sensitive nature of the goods;

- The number of different merchandise references to be stored.

And also ..

- The type of forklift used, which determines the maximum height of the installation and the width of the aisles;

- The skill and safety of forklift operators;

- Your budget.

Our experts can help you choose your product storage system.

By taking into account the above criteria as well as your processes and goods flows, we can help you define :

- The storage method best suited to your needs FIFO (First In - First Out) or LIFO (Last In - Last Out)

The amount of space required for equipment, depending on the type of handling, and whether single or double access is required.

- The degree of densification of your storage

We'll also advise you on the accessories you need to protect your storage rack and your staff, signposting and partitioning of spaces, and the right handling equipment or carts.

Discover our guide to storage methods → The different pallet storage solutions

The different pallet storage solutions

Here's the list of our pallet storage rack solutions that our experts can offer you, based on the criteria taken into account in the previous section.

In this section, we'll take a closer look at these different pallet rack solutions.

Fixed storage rack

This is the ideal solution for storing heavy or bulky products in complete safety. Its variants can be adapted to suit your needs and logistics flows. We recommend using this system for a large number of products, but with a low volume per product.

How the solution works :

This solution complies with the ABC storage method, which consists in storing goods according to their turnover rate (the greater the turnover, the closer the goods are placed to the operators and therefore easier to handle).

Accumulation storage rack

This storage solution for palletized loads is recommended for large volumes with a limited number of part numbers. With this pallet storage solution, the forklift enters the aisles to load or unload the pallets, whatever the level to be reached.

How the solution works :

- Drive In : Pallets are loaded and unloaded from the same side on the LIFO (Last In - First Out) principle;

- Drive Through: Pallets are loaded from one side and unloaded from the opposite side on the FIFO (First In - First Out) principle.

Carrier Pushback dynamic storage on carts

Carrier Pushback pallet racking is a dynamic pallet racking system on mobile carts. It can store up to 9 pallets deep. This solution complies with the LIFO (Last In - First Out) method, and enables one reference to be stored per location.

How the solution works :

- Pallets are deposited at the entrance to the aisle on a mobile frame sliding on a metal rail;

- Pallets move by pushing when loaded, and descend by gravity when unloaded.

Dynamic storage on rollers

This is a dynamic storage system on large rollers where pallets move by gravity. It enables the storage of a very large number of pallets of the same reference on each dynamic line.

How the solution works:

- FIFO (First In - First Out): pallets are loaded and unloaded on opposite sides. The pallet is deposited on one side and descends by gravity to the other side, where it is unloaded. Large number of pallets in depth;

- LIFO (Last In - First Out): Lines are loaded and unloaded from the same side. During loading, pallets are pushed back. When unloading, pallets move by gravity. Limited number of pallets in depth.

High-density storage with electric shuttle (pallet shuttle)

This solution is designed to increase pallet storage density and optimize logistics flows. It is ideal for high-volume, high-turnover products. With the high-density pallet rack, it is possible to store one reference per level, and a very large number of pallets of different dimensions in depth. This solution is available for LIFO (Last In - First Out) or FIFO (First In - First Out) methods.

How the solution works:

- The shuttle is deposited at the entrance to the aisle and moves along a rail inside the system;

- The shuttle moves the pallet to the first available location and back, and vice versa;

- The pallet shuttle is fully electric, equipped with a lithium battery and operated by remote control;

- This solution is also suitable for low-temperature warehouses;

- The pallet shuttle avoids the need to purchase specific forklifts to enter pallet racks.

All our storage solutions at a glance

Depending on your storage needs, we can offer you many other solutions such as storage platforms and industrial mezzanines, industrial metal shelving for light and medium-heavy loads, cantilever racking for long loads..

Contact us for your storage project, and we'll meet your requirements with a fast, comprehensive quote.

Do you have a project in mind?

Our 80-strong sales team in 12 branches across France, backed up by our 20-strong design office, can help you with all your needs.

I've got a project!