How to choose your retention tank?

Provost, France's leading manufacturer of shelving and storage solutions, supports you in all areas of your business, offering a complete range of retention solutions for hazardous and environmentally harmful products.

More than 80 technical sales staff and a design office of 20 technicians are on hand to offer you the solution best suited to your needs.

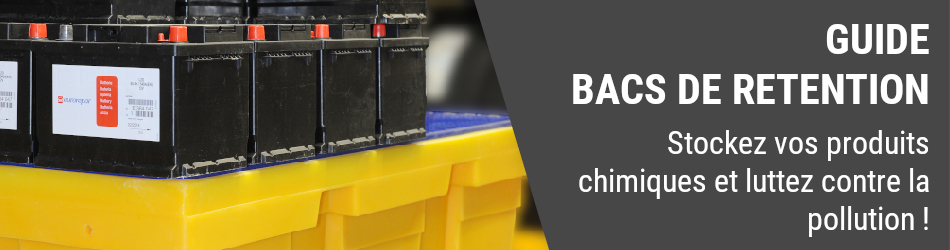

Retention bins for hazardous storage

Acids, glues, resins, degreasers, thinners, paints... Chemical agents are present in the workplace. Many chemicals can have harmful effects on people and the environment. Whether substances or mixtures, these hazardous products must be prevented, identified and stored efficiently.

To limit staff exposure to hazards, you need to organize your product storage either in a specific ventilated room, in an outside container, in a storage cabinet with retention tanks, or on a shelf equipped with steel or polyethylene retention tanks.

Retention bins, placed under containers, are used to recover liquids in the event of damage to stored containers (impacts, falls, fire, etc.).

Retention tank regulations

3 installation categories

- Compliance with departmental health regulations and/or labor code provisions.

- DUER (Single Risk Assessment Document)

- Compliance with safety regulations defined by the decree of February 2, 1998.

- Mandatory declaration to the prefecture;

- Compliance with specific regulations and orders relating to the activity carried out;

- By default, compliance with the provisions of the decree of February 2, 1998.

- Prefectoral authorization required before start-up.

- Compliance with safety regulations defined by the decree of February 2, 1998 and any additional prefectoral decrees.

To find out which category of facility you belong to, contact your local prefecture.

Capacity of your facility's retention tank regulated by the decree of October 4, 2010

For storage of containers with a unit capacity of over 250 liters:

Any storage of a liquid likely to cause water or soil pollution must be associated with a retention capacity whose volume is at least equal to the greater of the following two values:

- 100% of the capacity of the largest tank.

- 50% of the total capacity of the associated tanks.

Here are a few examples of how to apply this rule:

> 100% of the largest tank: 1000L

> 50% of total capacity of associated tanks: 500L

Retention volume to be respected: 1000L

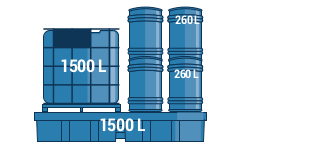

> 100% of largest tank: 260L

> 50% of total capacity of associated tanks: 520L

Retention volume to be respected: 520L

> 100% of largest tank: 1500L

> 50% of total capacity of associated tanks: 1270L

Retention volume to be respected: 1500L

For storage of containers with a unit capacity of 250 liters or less:

In this case, the retention capacity must be at least equal to:

- For flammable liquids (excluding lubricants), 50% of total drum capacity;

- For all other liquids, 20% of total drum capacity.

The spill containment system must be leakproof and resistant to the physical and chemical action of fluids.

> It must be possible to check the tightness of the associated tank(s) at any time.

> Tanks or containers containing incompatible products must not be associated with the same spill containment.

Chemical nature and compatibility

Identification of chemical products

In accordance with the European "CLP" (Classification, Labelling, Packaging) regulation, chemical product manufacturers are required by law to label each container and provide a "safety data sheet". This document provides information on the risks associated with the use of the substance, and the necessary storage arrangements. Provost also provides hazard pictograms to identify chemical products.

I discover the hazard pictograms →

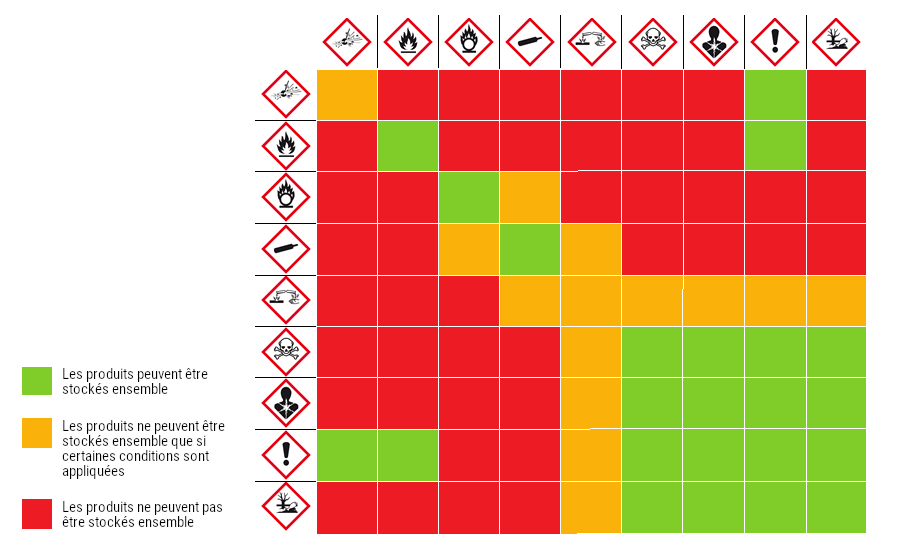

Chemical compatibility table

Some chemical agents are likely to interact with each other. Interactions that can cause explosions, fires, splashes or hazardous gas emissions. These incompatible products must be stored separately to avoid accidents.

IMPORTANT :

> Incompatible products must be stored separately to avoid any risk of mixing.

> For flammable products, store them in a fireproof cabinet.

What material should your bund be made of?

Steel bunds are not suitable for storing strong acids and bases. For these substances, you need to use polyethylene plastic bunds.

Discover polyethylene retention bins →

To help you choose the right retention bin for the product to be stored, a compatibility list exists!

I discover the steel or polyethylene compatibility list →

Do you have a project in mind?

Our 80-strong sales team in 12 branches across France, backed up by our 20-strong design office, can help you with all your needs.

I've got a project!